Specification

5052 aluminum strip for shutters

Source:Original

Editing:frank

Time:2025-03-19 16:02

5052 aluminum strip for shutters

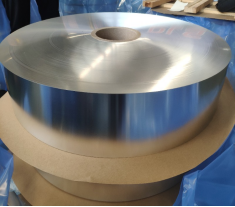

Aluminum Strip Introduction

5052 aluminum alloy is widely used in the manufacture of blinds due to its excellent corrosion resistance, weldability, plasticity and fatigue resistance. Its light weight and high strength make it the first choice for high-quality blinds, and it is also an important representative of high-performance aluminum alloys. In order to ensure that the product reaches the international advanced level in terms of safety, durability and aesthetics, the production and testing process strictly follows ANSI WCMA A100.1-2018 and ASTM B221 standards.

Application of 5052 aluminum strip in blinds

Main application areas

Louvers: The sunshade louvers made of 5052 aluminum strips have excellent elasticity and stability and are not easy to deform, ensuring the best shading and ventilation effects.

Window frame structure: 5052 aluminum strip is used in window frame production, which not only enhances the durability and stability of the overall structure, but also effectively prevents rust and prolongs the service life of the product.

Connectors and supporting structures: Some blinds use connectors made of 5052 aluminum strips to further enhance the structural strength of the windows and ease of installation.

Applicable scenarios

·Residential buildings: Suitable for home blinds, providing excellent ventilation, shading and aesthetic effects.

·Commercial buildings: Widely used in the exterior walls or indoor shading systems of office buildings, shopping malls and other buildings, which are both fashionable and practical.

·Industrial plants: In high temperature and humid environments, blinds made of 5052 aluminum strips can significantly improve durability and corrosion resistance. Keywords: industrial blinds, corrosion-resistant windows.

·Outdoor facilities: Suitable for open spaces such as balconies, terraces, and courtyards, which can provide both shading and privacy protection. Keywords: outdoor shading, courtyard blinds.

· Plain Aluminum Strip: Precision-rolled with a smooth surface, ready for direct use in blind manufacturing without additional treatment.

2. Rolling and Forming: Using hot rolling and cold rolling processes, aluminum sheets are gradually rolled to the required thickness and undergo precision surface treatment to ensure flatness.

3. Surface Treatment, Inspection, and Key Considerations:

1. Processes such as stretch leveling, cleaning, anodizing, or coating are applied to enhance aesthetics and corrosion resistance.

2. Surface Quality: The surface must be free from defects such as cracks, corrosion, dents, peeling, perforations, bubbles, folds, scratches, and metal or non-metallic imprints.

3. Cutting Edges: Cutting must be neat, without edge cracks, folds, burrs, or deformations that could affect coating application.

4. Coated Tape Surface Quality: The coating must be free from bubbles, cracks, discoloration, orange peel, edge buildup, pinholes, missing coating, color differences, black streaks, foreign particles, flow marks, blade marks, scratches, or scuffs.

5. The product undergoes rigorous testing for thickness, strength, ductility, and corrosion resistance to meet industry standards.

2. Select a Reliable Supplier: Choose suppliers with strong industry presence and good reputation to ensure product quality and comprehensive after-sales service.

3. Check Quality Certification: Ensure the aluminum strip meets ISO certification and authoritative quality inspection standards.

4. Sample Testing: Before bulk purchasing, obtain samples for testing to verify that the product's performance meets expectations.

5. Consider Cost-Effectiveness: Evaluate not only price but also product quality, durability, and after-sales support for a balanced investment.

✅ Strict Quality Control: Our products meet ISO, SGS, and other international certification standards, guaranteeing reliability.

✅ Diverse Surface Treatment Options: We offer color coating, anodizing, electrophoresis, and heat transfer printing, catering to various application needs.

✅ Customized Services: We provide personalized customization for different thicknesses, widths, and surface treatments (such as anodizing and coating) to suit various blind applications.

✅ Trusted by Global Customers: Our products are exported to Europe, America, Southeast Asia, and other regions, earning high customer satisfaction.

Aluminum Strip Introduction

5052 aluminum alloy is widely used in the manufacture of blinds due to its excellent corrosion resistance, weldability, plasticity and fatigue resistance. Its light weight and high strength make it the first choice for high-quality blinds, and it is also an important representative of high-performance aluminum alloys. In order to ensure that the product reaches the international advanced level in terms of safety, durability and aesthetics, the production and testing process strictly follows ANSI WCMA A100.1-2018 and ASTM B221 standards.

Application of 5052 aluminum strip in blinds

Main application areas

Louvers: The sunshade louvers made of 5052 aluminum strips have excellent elasticity and stability and are not easy to deform, ensuring the best shading and ventilation effects.

Window frame structure: 5052 aluminum strip is used in window frame production, which not only enhances the durability and stability of the overall structure, but also effectively prevents rust and prolongs the service life of the product.

Connectors and supporting structures: Some blinds use connectors made of 5052 aluminum strips to further enhance the structural strength of the windows and ease of installation.

Applicable scenarios

·Residential buildings: Suitable for home blinds, providing excellent ventilation, shading and aesthetic effects.

·Commercial buildings: Widely used in the exterior walls or indoor shading systems of office buildings, shopping malls and other buildings, which are both fashionable and practical.

·Industrial plants: In high temperature and humid environments, blinds made of 5052 aluminum strips can significantly improve durability and corrosion resistance. Keywords: industrial blinds, corrosion-resistant windows.

·Outdoor facilities: Suitable for open spaces such as balconies, terraces, and courtyards, which can provide both shading and privacy protection. Keywords: outdoor shading, courtyard blinds.

5052 Chemical Composition

| Element | Content (%) |

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 2.2~2.8 |

| Chromium (Cr) | 0.15~0.35 |

| Copper (Cu) | ≤0.1 |

| Iron (Fe) | ≤0.25 |

| Manganese (Mn) | ≤0.1 |

| Silicon (Si) | ≤0.4 |

| Zinc (Zn) | ≤0.1 |

| Other Individual Impurities | ≤0.05 |

| Total Other Impurities | ≤0.15 |

Mechanical Properties

| Property | Value |

| Brinell Hardness | 46~83 HB |

| Ultimate Tensile Strength (UTS) | 190~320 MPa |

| Yield Strength | 75~280 MPa |

| Shear Strength | 120~180 MPa |

| Shear Modulus | 26 GPa |

| Poisson's Ratio | 0.33 |

| Fatigue Strength | 66~140 MPa |

| Elongation at Break | 1.1~22% |

| Elastic Modulus | 68 GPa |

| Thermal Conductivity | 140 W/m-K |

| Specific Heat Capacity | 900 J/kg-K |

| Density | 2.7 g/cm³ |

| Electrical Conductivity (Volume) | 35% IACS |

Classification of Aluminum Strips

By Temper

| Temper | Characteristics |

| 5052-O | Annealed condition, maximum ductility, suitable for deep drawing processing |

| 5052-H32 | Moderately work-hardened, high strength, good durability, ideal for blind applications |

| 5052-H34 | Higher strength than H32, suitable for high-strength blinds |

| 5052-H36 | Further enhanced hardness, suitable for windows requiring strong wind resistance |

| 5052-H38 | Maximum hardness, used for high-load structures |

Classification by Surface Treatment

· Plain Aluminum Strip: Precision-rolled with a smooth surface, ready for direct use in blind manufacturing without additional treatment.

· Coated Aluminum Strip: Surface coated with special layers such as Polyester (PE) or Polyvinylidene Fluoride (PVDF) to enhance corrosion resistance and aesthetics.

· Anodized Aluminum Strip: Treated with an anodizing process to improve surface hardness and wear resistance, offering various color options for high-end architectural blinds.

· Embossed Aluminum Strip: Surface embossed for enhanced decorative appeal and wear resistance, widely used in commercial blinds.

Production Process of 5052 Aluminum Strip

1. Melting and Casting: Raw aluminum and alloying elements are mixed in precise proportions and melted in a high-temperature furnace to ensure uniform chemical composition.2. Rolling and Forming: Using hot rolling and cold rolling processes, aluminum sheets are gradually rolled to the required thickness and undergo precision surface treatment to ensure flatness.

3. Surface Treatment, Inspection, and Key Considerations:

1. Processes such as stretch leveling, cleaning, anodizing, or coating are applied to enhance aesthetics and corrosion resistance.

2. Surface Quality: The surface must be free from defects such as cracks, corrosion, dents, peeling, perforations, bubbles, folds, scratches, and metal or non-metallic imprints.

3. Cutting Edges: Cutting must be neat, without edge cracks, folds, burrs, or deformations that could affect coating application.

4. Coated Tape Surface Quality: The coating must be free from bubbles, cracks, discoloration, orange peel, edge buildup, pinholes, missing coating, color differences, black streaks, foreign particles, flow marks, blade marks, scratches, or scuffs.

5. The product undergoes rigorous testing for thickness, strength, ductility, and corrosion resistance to meet industry standards.

How to Choose High-Quality 5052 Aluminum Strip?

1. Define Your Needs: Determine the required thickness, width, and surface treatment based on the intended application to ensure it meets specific usage requirements.2. Select a Reliable Supplier: Choose suppliers with strong industry presence and good reputation to ensure product quality and comprehensive after-sales service.

3. Check Quality Certification: Ensure the aluminum strip meets ISO certification and authoritative quality inspection standards.

4. Sample Testing: Before bulk purchasing, obtain samples for testing to verify that the product's performance meets expectations.

5. Consider Cost-Effectiveness: Evaluate not only price but also product quality, durability, and after-sales support for a balanced investment.

Why Choose Henan Xinyi Aluminum?

As a leading international aluminum manufacturer, Henan Xinyi Aluminum has accumulated extensive experience in the aluminum alloy industry. We are committed to providing high-quality 5052 aluminum strip products to our customers.Our Advantages

✅ Advanced Production Equipment: We utilize internationally leading aluminum strip production lines to ensure stable product quality.✅ Strict Quality Control: Our products meet ISO, SGS, and other international certification standards, guaranteeing reliability.

✅ Diverse Surface Treatment Options: We offer color coating, anodizing, electrophoresis, and heat transfer printing, catering to various application needs.

✅ Customized Services: We provide personalized customization for different thicknesses, widths, and surface treatments (such as anodizing and coating) to suit various blind applications.

✅ Trusted by Global Customers: Our products are exported to Europe, America, Southeast Asia, and other regions, earning high customer satisfaction.

RELATED READ:

- Foil for electrolytic capacitors2015.3.19

- Copper-Clad Aluminum Wire (CCA)2015.3.19

- 5052 aluminum strip for shutters2015.3.19

- Application of aluminum semi-finished products in e2015.3.19

- Copper clad aluminum enamelled round wire2015.3.19