Specification

Copper-Clad Aluminum Wire (CCA)

Source:Original

Editing:za

Time:2025-03-21 11:26

Copper-Clad Aluminum Wire (CCA)

What is Copper-Clad Aluminum (CCA) wire?

In the field of electrical engineering, where the balance between cost-effectiveness and performance is crucial, Copper-Clad Aluminum (CCA) wire is gradually becoming a material of increasing attention. It is a bimetallic conductor with an aluminum core and a copper outer layer, achieved through advanced metallurgical processes to ensure a strong bond between the two materials. This unique structure combines the lightweight properties of aluminum with the excellent conductivity of copper, making it widely used in fields such as telecommunications, electronic devices, power systems, and renewable energy.

Core Advantages of Copper-Clad Aluminum (CCA) Wire

Significant Cost Efficiency:Compared to pure copper wire, CCA wire can save up to 40% in material costs, while also reducing weight by 40%, greatly lowering transportation and installation expenses.

Excellent High-Frequency Performance:Utilizing the "skin effect," CCA wire performs similarly to pure copper wire in high-frequency signal transmission (>5MHz), making it particularly suitable for high-frequency communication and radio frequency (RF) applications. The skin effect refers to the phenomenon where high-frequency alternating current concentrates on the surface of the conductor during transmission. Therefore, the copper layer on the outer surface of CCA wire provides excellent conductivity at high frequencies.

Superior Corrosion Resistance:The outer copper layer forms a protective barrier, effectively preventing the aluminum core from exposure to air and avoiding oxidation, which could lead to poor contact and extending its service life.

Lightweight Design:CCA wire is about 40% lighter than pure copper, making it ideal for applications in aerospace, automotive, and mobile electronics, where weight is a critical factor.

Electrical Performance Parameters

Resistivity: The resistivity of CCA wire is typically higher than that of pure copper wire but lower than pure aluminum wire. At 20°C, the standard resistivity of pure copper is 1.68×10⁻⁸ Ω·m, while the resistivity of CCA wire is around 2.65×10⁻⁸ Ω·m.

Conductivity: The conductivity of CCA wire is lower than that of pure copper wire but higher than pure aluminum wire. The standard conductivity of pure copper is 5.96×10⁷ S/m, while the conductivity of CCA wire is approximately 3.77×10⁷ S/m.

DC Resistance: Due to the aluminum core, the DC resistance of CCA wire is higher than that of pure copper wire of the same specification, which must be considered in low-frequency or DC applications.

Application Industries

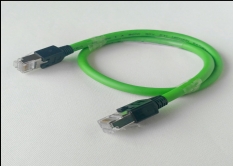

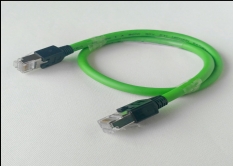

Telecommunications Industry: Coaxial cables, Ethernet cables, 5G, and radio frequency signal transmission. In the construction of 5G base stations, Copper-Clad Aluminum (CCA) wire is widely used for high-frequency signal transmission, reducing construction costs and weight.

Consumer Electronics: Speaker and audio cables, transformer windings and inductors, power cords for household appliances. In lightweight laptops, Copper-Clad Aluminum (CCA) wire is used for power cords, reducing the overall weight.

Power Systems: Low-current distribution, bus ducts, and panel wiring (requiring proper terminal handling). When Copper-Clad Aluminum (CCA) wire is used in power systems, specialized copper-aluminum transition connectors must be used to prevent connection loosening and heating caused by the electrochemical reaction between the two metals. During terminal handling, it is essential to ensure the connection surface is clean and apply conductive paste to reduce contact resistance.

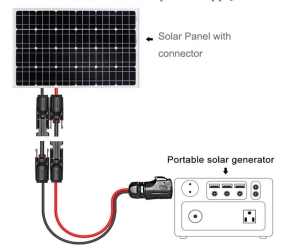

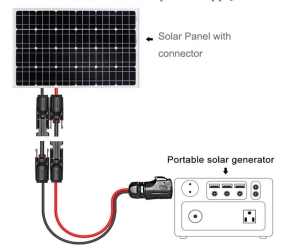

Renewable Energy: Solar panel wiring, wind turbine power transmission. In solar power systems, Copper-Clad Aluminum (CCA) wire is used to connect solar panels, reducing installation costs and weight.

Copper-Clad Aluminum (CCA) Wire vs. Other Conductors

Certification

o UL Certification refers to products meeting the safety standards of Underwriters Laboratories, such as UL 1581 for wire and cable.

o RoHS Certification refers to products meeting the European Union's Restriction of Hazardous Substances directive, limiting the use of harmful substances like lead, mercury, and cadmium.

Frequently Asked Questions (FAQ)

1. Q: What is the lifespan of Copper-Clad Aluminum (CCA) wire?

A: With proper installation and maintenance, CCA wire can last over 10 years. Regular inspection of the connections is necessary to prevent oxidation issues.

2. Q: How to properly connect Copper-Clad Aluminum (CCA) wire?

A: When connecting CCA wire, specialized copper-aluminum transition connectors must be used to prevent connection loosening and heating caused by electrochemical reactions between the two metals. Before making the connection, ensure the surface is clean and apply conductive paste to reduce contact resistance.

3. Q: What are common quality issues with Copper-Clad Aluminum (CCA) wire?

A: Common quality issues include uneven copper layer thickness, eccentric aluminum core, surface scratches, and oxidation. These issues can affect the wire's conductivity, corrosion resistance, and lifespan. Therefore, when purchasing, choose products from reputable brands and carefully inspect the appearance and certifications.

What is Copper-Clad Aluminum (CCA) wire?

In the field of electrical engineering, where the balance between cost-effectiveness and performance is crucial, Copper-Clad Aluminum (CCA) wire is gradually becoming a material of increasing attention. It is a bimetallic conductor with an aluminum core and a copper outer layer, achieved through advanced metallurgical processes to ensure a strong bond between the two materials. This unique structure combines the lightweight properties of aluminum with the excellent conductivity of copper, making it widely used in fields such as telecommunications, electronic devices, power systems, and renewable energy.

Core Advantages of Copper-Clad Aluminum (CCA) Wire

Significant Cost Efficiency:Compared to pure copper wire, CCA wire can save up to 40% in material costs, while also reducing weight by 40%, greatly lowering transportation and installation expenses.

Excellent High-Frequency Performance:Utilizing the "skin effect," CCA wire performs similarly to pure copper wire in high-frequency signal transmission (>5MHz), making it particularly suitable for high-frequency communication and radio frequency (RF) applications. The skin effect refers to the phenomenon where high-frequency alternating current concentrates on the surface of the conductor during transmission. Therefore, the copper layer on the outer surface of CCA wire provides excellent conductivity at high frequencies.

Superior Corrosion Resistance:The outer copper layer forms a protective barrier, effectively preventing the aluminum core from exposure to air and avoiding oxidation, which could lead to poor contact and extending its service life.

Lightweight Design:CCA wire is about 40% lighter than pure copper, making it ideal for applications in aerospace, automotive, and mobile electronics, where weight is a critical factor.

Electrical Performance Parameters

Resistivity: The resistivity of CCA wire is typically higher than that of pure copper wire but lower than pure aluminum wire. At 20°C, the standard resistivity of pure copper is 1.68×10⁻⁸ Ω·m, while the resistivity of CCA wire is around 2.65×10⁻⁸ Ω·m.

Conductivity: The conductivity of CCA wire is lower than that of pure copper wire but higher than pure aluminum wire. The standard conductivity of pure copper is 5.96×10⁷ S/m, while the conductivity of CCA wire is approximately 3.77×10⁷ S/m.

DC Resistance: Due to the aluminum core, the DC resistance of CCA wire is higher than that of pure copper wire of the same specification, which must be considered in low-frequency or DC applications.

Application Industries

Telecommunications Industry: Coaxial cables, Ethernet cables, 5G, and radio frequency signal transmission. In the construction of 5G base stations, Copper-Clad Aluminum (CCA) wire is widely used for high-frequency signal transmission, reducing construction costs and weight.

Consumer Electronics: Speaker and audio cables, transformer windings and inductors, power cords for household appliances. In lightweight laptops, Copper-Clad Aluminum (CCA) wire is used for power cords, reducing the overall weight.

Power Systems: Low-current distribution, bus ducts, and panel wiring (requiring proper terminal handling). When Copper-Clad Aluminum (CCA) wire is used in power systems, specialized copper-aluminum transition connectors must be used to prevent connection loosening and heating caused by the electrochemical reaction between the two metals. During terminal handling, it is essential to ensure the connection surface is clean and apply conductive paste to reduce contact resistance.

Renewable Energy: Solar panel wiring, wind turbine power transmission. In solar power systems, Copper-Clad Aluminum (CCA) wire is used to connect solar panels, reducing installation costs and weight.

Copper-Clad Aluminum (CCA) Wire vs. Other Conductors

| Wire Type | Cost | Conductivity | Corrosion Resistance | Best Application Scenarios |

| Copper-Clad Aluminum | Low | Medium (High at high frequencies) | Good | Telecommunications, Electronics, Renewable Energy |

| Pure Copper | High | Excellent | Excellent | High-power transmission, Critical electrical systems |

| Pure Aluminum | Low | Good | Poor | High-voltage power lines (requires corrosion protection) |

Certification

o UL Certification refers to products meeting the safety standards of Underwriters Laboratories, such as UL 1581 for wire and cable.

o RoHS Certification refers to products meeting the European Union's Restriction of Hazardous Substances directive, limiting the use of harmful substances like lead, mercury, and cadmium.

Frequently Asked Questions (FAQ)

1. Q: What is the lifespan of Copper-Clad Aluminum (CCA) wire?

A: With proper installation and maintenance, CCA wire can last over 10 years. Regular inspection of the connections is necessary to prevent oxidation issues.

2. Q: How to properly connect Copper-Clad Aluminum (CCA) wire?

A: When connecting CCA wire, specialized copper-aluminum transition connectors must be used to prevent connection loosening and heating caused by electrochemical reactions between the two metals. Before making the connection, ensure the surface is clean and apply conductive paste to reduce contact resistance.

3. Q: What are common quality issues with Copper-Clad Aluminum (CCA) wire?

A: Common quality issues include uneven copper layer thickness, eccentric aluminum core, surface scratches, and oxidation. These issues can affect the wire's conductivity, corrosion resistance, and lifespan. Therefore, when purchasing, choose products from reputable brands and carefully inspect the appearance and certifications.

Previous :5052 aluminum strip for shutters

Next :None

RELATED READ: