Enameled Aluminum Wire

How to Check Aluminum Strip Slitting Accuracy

Slitting Accuracy and Tolerance of Aluminum Strips

High-precision slitting is essential for aluminum strips used in transformer windings, cable shielding, and electronic components. Poor accuracy can lead to edge defects, winding issues, and energy loss. Here’s how to ensure slitting quality meets application standards.

Width Tolerance

Standard width tolerance ranges from ±0.2 mm for general use to ±0.05 mm for precision-grade aluminum strips. Measurements are typically done using laser gauges or digital calipers across several sample points.

Edge Quality

Smooth, burr-free edges ensure safety and allow for automated winding without material jams. Edges should be free of cracks, fraying, or warping.

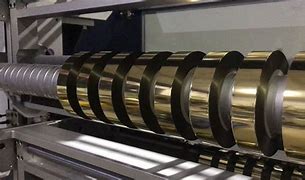

Coil Consistency

Even tension and alignment across the coil are signs of quality slitting. Misaligned or unevenly recoiled strips can affect downstream processes.

Thickness Control

Consistent thickness across the width supports reliable conductivity and heat dissipation. Use inline thickness sensors or micrometers for sampling.

Blade Condition

Well-maintained slitting blades are critical. Blade wear or incorrect clearance causes jagged edges and width variations. Regular calibration ensures optimal performance.

Inspection Standards

Reference international standards such as GB/T 3880, ASTM B209, and ISO 6361 to verify conformity. These provide benchmarks for width tolerance and edge quality.

Reliable Supply Matters

Choose aluminum strip suppliers who provide inspection reports, burr-free edges, and custom slitting services. A trusted partner can reduce production risk and improve performance.

Need Precision Aluminum Strip?

YourCompanyName delivers tight tolerance aluminum strips for transformers, cables, and electronics. Request a quote today and get expert slitting solutions tailored to your needs.

Frequently Asked Questions (FAQ)

What is the standard tolerance for aluminum strip width?

Standard tolerance is ±0.2 mm, while high-precision applications may require ±0.05 mm or better.

How do you measure slitting accuracy?

Accuracy is measured using digital calipers or laser width detectors at multiple coil points during and after slitting.

Why is burr-free edge important?

Burr-free edges prevent electrical insulation damage and ensure smooth winding on transformer machines.

Can I request custom coil width and thickness?

Yes. We offer aluminum strips in custom widths and thicknesses according to your exact specifications.

Do you provide inspection reports with each order?

Yes, we provide full dimensional inspection and slitting quality reports upon request.