Enameled Aluminum Wire

Why Dry Transformers Use Aluminum Strip Windings

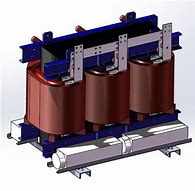

Why Dry-Type Transformers Commonly Use Aluminum Strip Windings

In modern power distribution, dry-type transformers play a key role in indoor, commercial, and high-safety applications. Unlike oil-immersed transformers, dry-type models use air cooling and require materials that are safe, efficient, and cost-effective. Aluminum strip windings have become the standard choice in this sector. Here's why.

Cost Efficiency

Aluminum is significantly more affordable than copper. By using aluminum strip windings, transformer manufacturers can lower production costs without sacrificing performance. This is especially attractive for medium-voltage systems used in urban and industrial settings.

Light Weight

Aluminum weighs only about one-third as much as copper. This reduces the overall transformer weight, making transport and installation easier, particularly in rooftop or indoor environments where floor loading is limited.

Sufficient Electrical Conductivity

Although aluminum has slightly lower conductivity than copper, its performance is sufficient when designed properly. Wider or thicker windings can be used to match the desired current-carrying capacity.

Good Thermal Performance

Aluminum has excellent heat dissipation characteristics. In dry-type transformers where air cooling is used, aluminum strips help maintain stable operating temperatures, ensuring longer service life.

Easy Processing and Forming

Aluminum strip is soft and easy to form, which suits automated winding equipment. This enhances production efficiency and reduces labor costs in transformer factories.

Safety and Corrosion Resistance

Dry-type transformers are often used in high-safety environments like hospitals, office buildings, and data centers. Aluminum's oxide layer provides natural corrosion resistance, reducing maintenance and fire risk.

Availability and Supply Stability

Aluminum is widely available globally and is not as affected by geopolitical or supply chain issues as copper. This ensures stable long-term procurement for transformer manufacturers.

Aluminum strip windings offer a perfect balance of cost, safety, and performance for dry-type transformers. As demand for efficient and fire-resistant electrical equipment grows, aluminum continues to dominate this application field.

FAQ: Aluminum Strip in Dry-Type Transformers

Is aluminum as reliable as copper in transformer windings?

Yes. When properly designed, aluminum provides reliable performance, especially in dry-type transformers up to 35kV.

What grades of aluminum strip are used in dry transformers?

Common grades include 1060, 1070, and 1350 aluminum, known for high conductivity and formability.

Does aluminum increase energy loss in transformers?

Not significantly. Engineers compensate with larger cross-sections to keep resistance low. Efficiency remains high.

Are aluminum coils safe for indoor use?

Yes. Aluminum's self-oxidizing surface and high melting point make it safe and fire-resistant for indoor applications.

Is aluminum more difficult to connect than copper?

It requires different connection techniques, but with proper lugs and clamps, aluminum connections are stable and secure.